Material to prevent brain injuries backed by NFL

16 December 2015

Novel 3D-printed material developed by University researchers receives funding in NFL-backed Head Health Challenge

Funding has been awarded to world-leading, US-based helmet designer and manufacturer, Roy Burek of Charles Owen Inc., to develop a novel material created by researchers from Cardiff University’s School of Engineering that can improve the safety of athletes, members of the military and others from brain injuries by better absorbing and dissipating impact.

The funding has been awarded by a partnership of the National Football League (NFL), Under Armour, GE, and the U.S. Department of Commerce’s National Institute of Standards and Technology (NIST), to support the discovery, design and deployment of advanced materials.

Charles Owen Inc. and Cardiff University will use the prize money to fund a 12-month project that will use state-of-the-art 3D printing and high-performance computing technology to develop the unique, energy-absorbing material further.

The team is among four winners to secure an initial $250,000 (£165,000) as part of Head Health Challenge III, an open innovation competition to advance their work in developing these materials.

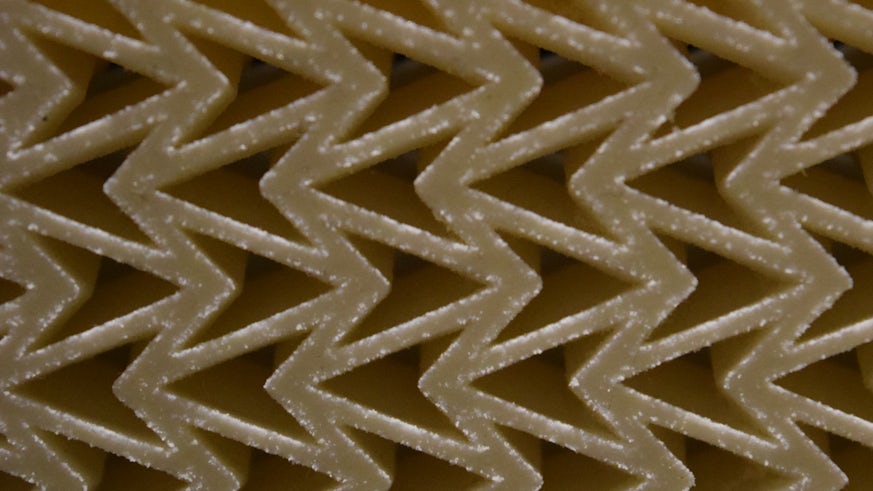

The multi-layered, elastic material, called C3, has been developed in collaboration with the University of Cambridge. It can be precisely designed using mathematical modelling and tested using high-performance computers to enable it to be ultimately tailored for specific impact scenarios.

This allows the team to test various designs before building the material with a 3D printer, which is a much more efficient and cost-effective method compared to traditional techniques. During the 3D printing process a polymer-based powder is fused into a specific shape by a laser, which solidifies the material to form a strong, flexible structure.

Structures can be designed in such a way that impact energy can be dissipated relatively easily, making it an ideal material to use in protective clothing and accessories.

Throughout the year, researchers from the School of Engineering will work closely with Charles Owen, Inc., to fine tune the material and test its robustness against a number of different impact scenarios.

Roy Burek, President & CEO of Charles Owen, Inc. said: “My grandfather, Charles Owen, started making helmets to protect the British soldiers in 1911 before moving onto motorcycle helmets in 1925, and then equestrian helmets (particularly jockey helmets) in 1938.

“This long and illustrious record in manufacturing innovative products that increase head safety has kept the brand at the center of helmet development for over 100 years. It has only been in the past 15 years that our knowledge of how the brain is injured and how to best protect it has dramatically changed along with the design and manufacture of helmets. I am thrilled to be part of a project that pushes the development of totally new protective technologies and materials so that we can better prevent brain injuries in multiple areas.”

Dr Peter Theobald, a Senior Lecturer at Cardiff University who leads on the project, said: “Head injury prevention strategies have remained relatively stagnant versus the evolution of other technologies. Our trans-Atlantic collaboration with Charles Owen Inc. has enabled us to pool our highly relevant skills and expertise in injury prevention, mechanics, manufacturing and commercialisation.

“This approach has already enabled us to develop C3 which shows great promise to better absorb the vertical and horizontal components of an oblique impact. This highly prestigious award provides us with a platform to continue developing C3 towards our ultimate goal of achieving a material that provides a step-change in head health and protection, whilst achieving metrics that ensure commercial viability.”