3D tech saves international sports star

11 April 2018

When Dan Biggar’s trusty kicking tee was left in tatters after 15 years of service, the Welsh rugby international was in desperate need of finding a replacement.

Yet unearthing something with the familiar look and feel as the tee he has used since he started playing for Gorseinon and Swansea school boys at the age of 14 proved to be particularly challenging.

Luckily for him, an existing partnership between the Welsh Rugby Union (WRU) and Cardiff University led to experts creating an exact replica using state-of-the-art 3D scanning and printing technology.

The efforts were led by Professor David Marhsall, an expert in computer vision from the University’s School of Computer Science and Informatics, who works closely with the WRU’s Head of Performance Analysis on match video analysis software.

“It was over a coffee that myself and Rhodri [WRU’s Head of Performance Analysis] started brainstorming and came up with the idea of producing an identical replica of Dan’s tee using a combination of 3D scanning and printing at the University,” Professor Marshall said.

Alongside PhD student David Williams, Professor Marshall used an Artec Space Spider 3D scanner to take multiple images of Dan’s kicking tee from various angles.

Using computer software, the images were then cleaned up and stitched together to form a complete 3D computerised representation of the kicking tee.

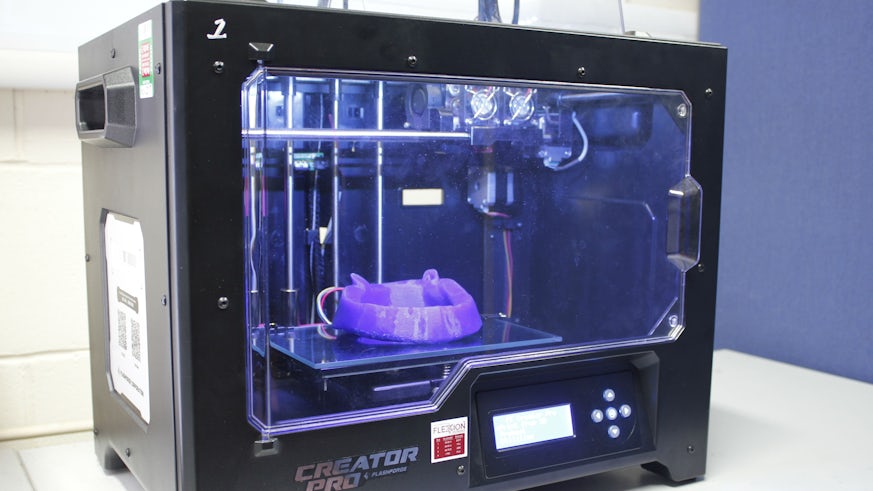

This image was then sent to Dr Peter Theobald, from the School of Engineering, who, along with his PhD student Benjamin Hanna, was able to produce a replica of the kicking tee using a 3D printer.

A 3D printer works by building an object from the bottom up, laying down layers of material in a highly organised and mechanical way until the final object is created. As a result of this layering process and the lack of human control needed, a 3D printer is able to produce highly complex structures.

The kicking tee was made from a filament-based thermoplastic polyurethane material called ‘Ninjaflex’ and took around 72 hours to fully print.

Dr Theobald has collaborated with a number of sports organisations in the past specifically on projects aimed at developing materials to reduce head injuries in sport.

The team at the University have now created a number of replica kicking tees for Dan, which he has used on duty for Wales, the Ospreys and the British and Irish Lions.

"I'm not particularly sentimental, it's more about routine, habit and feeling familiar. Whenever I've used another tee, it's never felt quite the same," Biggar told WalesOnline.

"The last thing I want to do is change tee and for me to have a bad psychological effect or anything like that. I could never quite find a replica like it once it was unusable, so fair play to the guys from Cardiff University.

"They've been absolutely brilliant and moulded a new one using 3D technology which is really impressive. It has the same marks and indentations. It's the same material as well and I'm really, really grateful to them. It's been brilliant and hopefully these can see me through to the end of my career. They're making a few spares for me just in case I leave it on a plane or in a stadium somewhere.”